Garage Railroad

Saturday, August 27, 2011

Module construction

We've (kids+me) made two 2' x 4' frames (well, 2' x 4' 1.5" frames). We used the Free-mo N suggestions: 6" high by 24" wide 3/4" birch plywood end pieces, then the same plywood but 4' long by 4" wide for the side boards (thus the overall 4' 1.5" length: we could use two 2' x 4' plywood boards and minimize cuts). Glued and screwed (using a Kreg jig) the frames together. Before this assembly, clamped the two endplates that would touch together, then drilled two holes, each of one inch diameter, on either side of the midpoint so that wired could pass between (Free-mo N doesn't do this, and instead runs wire under module ends). To help alignment between the two sections, each has two 5 mm diameter metal pegs that fit into complementary holes in the other module. Many of the deviations from Free-mo suggestions come because I want to be able to slide the modules together on a table or shelf and so there won't always be room for attaching a C-clamp (though the modules are made so this is possible). Each module also has eight felt feet underneath so they can be put on various surfaces without damaging them (you can see them in the photos elevating the module above the driveway). I have also attached the pink foam for the surface (attached using Liquid Nails for Projects, though they're a flush fit to the end pieces).

Overall, this is coming out neater and stronger than I expected. The one thing I've noticed is that I find a 2' x 4' module awkward to carry if it is to be kept level: reaching under to hold the opposite side doesn't feel secure, nor does grabbing the end pieces. I'm sure with practice it will be better.

Friday, August 26, 2011

Painting foam

Pink or blue extruded foam insulation has become popular for model railroads: lightweight, fairly rigid, easy to shape. Following Free-mo N suggestions, my layout modules were to be covered with 2" of foam. I bought a 4' x 8' x 2" sheet at my local home improvement store (the greatest advantage of living outside of California is that such foam is once again readily available). I found that the sheet would not fit in our minivan (at least, not without removing several child car seats to allow the van seats to be dropped down), so it was back to the store for a saw. Fortunately, the foam I got was scored on its center line, so deepening the cut and then snapping the foam went well.

Many model railroads spend an extended time in the "Plywood Pacific" stage: track down, railroad operational, but no scenery, just the wood/foam/homasote/etc. supporting the track. Since I'll be doing winter scenery, I thought that I could paint the foam white before track laying: far from finished scenery, but less jarring to the eye than bright pink during the Plywood Pacific stage. I thought that I could just quickly spray the foam with white spray paint before using it.

I knew that foam was sensitive to various chemicals, thus the common advice in the model railroad press to use foam-safe adhesives. So I was careful to buy spray paint intended for plastics, even noting that polystyrene is listed on the label as one of the plastics it was safe for. A few seconds after starting to spray the foam, it became apparent that the paint might be great for plastics, but not this foam. The foam kept bubbling and was gradually being eaten away. I wiped off the paint. You can see the results below (zoom in on the right). Basic moral: use acrylics/latex. Less noxious and won't eat your benchwork.

Many model railroads spend an extended time in the "Plywood Pacific" stage: track down, railroad operational, but no scenery, just the wood/foam/homasote/etc. supporting the track. Since I'll be doing winter scenery, I thought that I could paint the foam white before track laying: far from finished scenery, but less jarring to the eye than bright pink during the Plywood Pacific stage. I thought that I could just quickly spray the foam with white spray paint before using it.

I knew that foam was sensitive to various chemicals, thus the common advice in the model railroad press to use foam-safe adhesives. So I was careful to buy spray paint intended for plastics, even noting that polystyrene is listed on the label as one of the plastics it was safe for. A few seconds after starting to spray the foam, it became apparent that the paint might be great for plastics, but not this foam. The foam kept bubbling and was gradually being eaten away. I wiped off the paint. You can see the results below (zoom in on the right). Basic moral: use acrylics/latex. Less noxious and won't eat your benchwork.

Monday, July 11, 2011

OPSIG industry DB

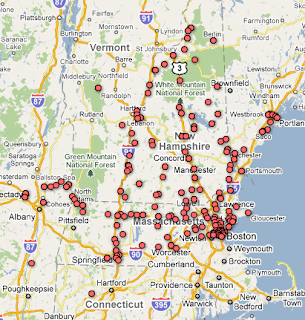

The OPSIG is a special interest group focusing on railroad operations, especially as they apply to model railroads. They maintain a database of real world and fictional industries, including localities, serving railroads, and what was shipped and received. It has tens of thousands of entries, split across four text files. Doing it in this way is a great idea, as these are easy to reuse (as opposed to locking them in some proprietary format). I ran a few scripts to clean them up (convert things like B&M, BM to be BM, have four digit years), pruned out non-real-world industries, and put it in Google Fusion Tables. This allows automatic geocoding (converting "Dover, NH" to a latitude and longitude) to put industries on the map and also allows filtering. Results can be viewed as a table or a map. You can filter for just industries served by the B&M (table or map), for all industries dealing with paper, or even combined things, like all auto-related industries served by UP in California (here).

The main page for the database is here.

Note that there are some weirdnesses. Some of the geocoding is off (a few Arizona localities are placed in Mexico), some of the raw data just seems wrong (like a railroad being given an industry in a weird part of the country for that line). Points in the same locality (New York, NY) overlap each other, so it looks like each place has one or zero industries (though don't forget about filtering). Overall, though, it should be pretty useful. I made it because I wanted to look at some of the industries served by the B&M in various towns, but then I figured, why not just do the general solution, as the data are already there?

The credit for this goes to the members of the OPSIG who created and maintain this amazing database, as well as Google for its free Google Fusion Tables tool. Remember that while the database is a product of the OPSIG, this particular use of it isn't, so the blame for any oddness should go to me, not them. They are still accepting new data. I'm not going to spend a lot of time keeping this up (my hobby is model railroading, not database creation) but there are ways to add collaborators to the document to make changes.

Sunday, July 10, 2011

Free-mo N

I'd been thinking of making my layout as a set of Ntrak modules (even went so far as to buy their booklets) but didn't want the whole three mainlines thing. I then decided to do the garage as one big shelf, but I haven't been working on it. Also, I've been growing concerned that it's not flexible: when we move, if I want to try modeling another area, etc., I'm stuck. I read about European Freemo and was intrigued, and heard about it being done in the US (but with an extra hyphen: Free-mo). It's a nice concept: specify the ends, so modules fit together, specify good track standards, and leave the rest up to the modeler. It's designed more for operation than display -- while Ntrak has 3 main lines with lots of action, Free-mo has a single main line (usually), and the European groups sometimes just rent out a large room for an operating session just for operators. They do have displays, however: I remember seeing a multi-legged centipede of a layout at a model railroad show that in retrospect probably was a Free-mo layout. There are both HO and N scale standards. The standards include scenery standards to keep modules consistent (no Mojave desert module sitting next to autumn in New Hampshire). However, I'd like to do winter scenery, so it won't be Free-mo compatible. This isn't a criticism of the Free-mo standard -- I think their scenery standard makes sense, just not what I want to do for my home layout [they also prohibit Peco code 55 track and turnouts (wrong tie spacing), which I've already invested in]. However, I will adopt basically their standards for everything else (track feeders 24 gauge or bigger, bus wire 12 gauge, butt joints between modules) -- if experts hash out the best way to do something, it's a good idea to go with that absent other information.

Sunday, March 27, 2011

Carl Arendt site backup

An important influence on my layout thinking has been the site on micro/small layouts curated by Carl Arendt. It is rich with great ideas for fitting operations and beauty into small spaces. With his passing, I was concerned that his heirs might not be able to keep up his site (in the wave of things to deal with, ensuring that the web host gets a check might not be top priority). So I downloaded his site as a hedge against this, so that if it does disappear, someone can resuscitate his work using the backup. The backup is a compressed zip file of 113 MB at http://snipurl.com/carendtzip. It was made on a virus-free Mac, but like all internet files, scan it for viruses or other nasty bits before use (and let me know via comments if you find any). Hopefully, others will take over his work and keep his site alive.

Saturday, January 22, 2011

Elevation profiles

Looking at Google Maps API for a different project, came across a demo map that lets you enter a route and then it will plot elevation along that route. The path between the two or more points can be direct (straight line) or along optimal road, bike, or walking paths (not rail). Since rail lines and road lines, especially highways, follow similar routes, this can be a handy thing for estimating the elevation profile (and thus locations of potential helper districts and other slope-based features) along a prototype or freelanced rail route. Here is a screenshot showing the elevation profile from Sacramento, CA, to Reno, NV, which goes through Donner Pass.

Wednesday, January 19, 2011

Design decisions

Design decisions so far (also see schematic above):

- Peco Code 55 N scale track, with electrofrogs: reported to operate well (electrofrogs are good for short wheelbase engines), look fairly good, but still be able to run deep flange cars like Microtrains' releases. No minimum turnout size specified yet.

- 11" minimum radius: allows turnback on the shelf but can run the trains I want (i.e., Kato's N scale RDC is supposed to operate on curves as tight as 9 3/4"). Won't look great, but the only tight curves will be in staging. The visible layout will just have very broad curves (though need to think about curves through turnouts).

- Train length: maximum train length is set at 37", which is sufficient for a train of ~10 freight cars. Visual tests suggest this looks like a moderate-length train, at least to me. Passenger trains should look much shorter than freight trains, so this means my passenger trains will probably only be two, maybe three, coaches long. It'd be great to run freight trains of 30 cars, but I don't want to devote that much space to staging (storing a train of that length at each end means about 14' of the 19' length would be used for staging, though of course you could stage in other ways) and I want to have trains short enough that they visually go from one "place" on the layout to another "place".

- Shelf design: metal brackets on tracks mounted to studs supporting a 1x2 frame (with 2x2 pieces running the length of the layout) covered with a layer of 1/4" ply. I will be putting 2" foam on top of this.

- At each end, an automated sector plate with a turnback curve and storage for three or more trains. One prototype built, still tweaking it.

- B&M main line going from one end of the layout to the other (basically on diagonal across the 19' x 2' layout footprint). This line has most of the focus and development (yard, industries). The intersecting railroad will run on the opposite diagonal and may be hidden or at least obscured over some of its length. There will be a crossing and interchange track where the lines intersect. These lines will connect to the sector plates at each end.

- A sneakback track at the back of the modeled layout (hidden with a low hill or other scenery, but accessible). This allows trains to run from one sector plate to the other. For instance, an RDC could run from left to right across the visible layout, enter the turnback loop on the sector plate, run on the sneakback track to the other turnback loop, and repeat the trip. This allows things like a commuter rush in one direction to be modeled with one set of equipment.

Subscribe to:

Posts (Atom)